Selecting the right helmet plays an important role in operator safety and comfort, and can also help improve efficiency, productivity, and weld quality. These are all factors that impact a welding operation’s bottom line.

An important consideration when selecting the right helmet for the application is the type and quality of lens used in the helmet.

At the most basic level, a welding lens is certified to protect the welding operator from the ultraviolet (UV) and infrared (IR) rays of the welding arc. In addition to protecting from harmful rays, an auto-darkening lens uses optical (and sometimes electromagnetic) sensors to change from a “light” state to a “dark” state when an arc is struck. Recently, new technologies have led to improvements for auto-darkening welding lenses.

The latest auto-darkening lens technology from Miller — ClearLight Lens Technology — improves a welder’s visibility by allowing a greater range of colors to come through the lens — giving welders a clearer view of the weld pool and surrounding workpiece while welding. Lenses with this technology are also designed to reduce eye strain when the operator is not welding, enabling the operator to leave his or her helmet down during pre-weld setup or finishing work. This leads to greater efficiency and continuous protection.

Benefits for safety and productivity

There are more than 15,000 welding equipment-related eye injuries a year, according to the U.S. Consumer Product Safety Commission. Eye injuries account for roughly 25 percent of all injuries to welding operators, and studies suggest that up to 90 percent of occupational eye injuries are preventable.

Injuries in the manufacturing or industrial welding environment most commonly occur when the operator is not welding and has the helmet in the up position. ClearLight Lens Technology, which reduces eye strain by providing greater clarity and a brighter light state, gives operators the capability to keep the helmet down when performing non-welding tasks, like grinding or cleaning. In the past, it was necessary to raise the helmet up for a clear line of sight.

Beyond the safety benefits of using ClearLight Lens Technology, the enhancements offer additional benefits that can help improve productivity.

When welding operators can clearly see the weld pool and surrounding workpiece, it can contribute to higher-quality completed welds and less rework — saving time and money. ClearLight Lens Technology makes it easier for welders to do their jobs, potentially leading to increased throughput.

Seeing more colors

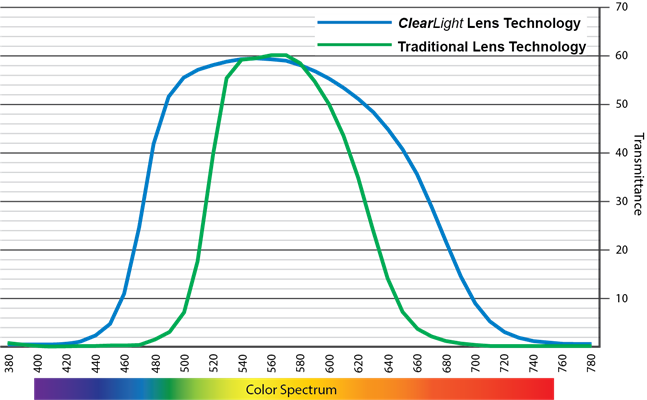

ClearLight Lens Technology allows more wavelengths along the color spectrum to come through the welding filter and auto-darkening lens.

Where previous filter technology prevented some colors from passing through — which resulted in the operator seeing an artificial yellow, green, or blue tint — ClearLight Lens Technology allows colors commonly emitted during welding to pass through the lens filter, providing a more color-neutral lens. To illustrate this improvement, the graphic below shows transmittance percentage (y-axis) along the wavelength light scale (x-axis). The green line shows the color band resulting from traditional lens technology, while the blue line shows the wide-band filter of newer advanced lenses. The display is a good representation of the additional colors that an operator can see when welding with ClearLight Lens Technology.

Even when not welding, an operator benefits from ClearLight Lens Technology. The heightened contrast in colors makes it easier to see peripheral items when in between welds – hopefully leading to increased “helmet down” time.

A brighter light state

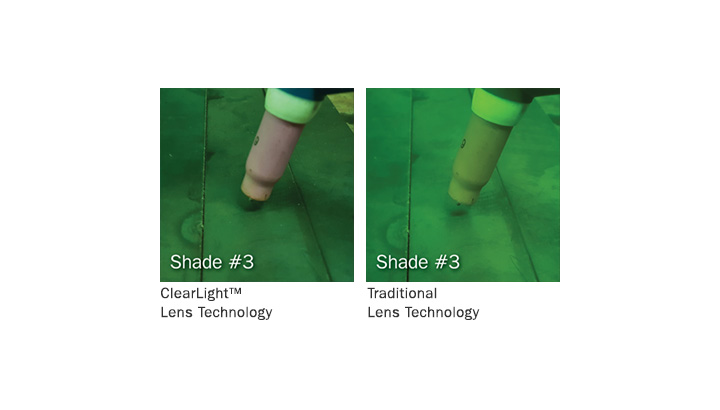

ClearLight Lens Technology provides a brighter light state. Light state refers to the state of the lens when it is not darkened for welding. Light state is measured on a numeric scale that represents how much light is being filtered out. This scale typically runs from shade 4 to 13 for welding helmets. The higher the number, the more light is being filtered out and the darker the lens. A shade 13 would be a darkened lens for high-amperage welding, for example.

The ability to achieve a brighter light state with ClearLight Lens Technology — which is a three on the scale — means the operator has a brighter view when the helmet is down and he or she is not welding. A helmet that provides a light state of three offers a noticeably brighter light state than does a helmet with a light state of four.

A brighter light state from ClearLight Lens Technology offers numerous benefits. It can reduce the number of times an operator removes his or her helmet, as well as how often they raise the helmet to the up position. Like enhanced contrast in a wide-band lens, a brighter light state can reduce eye strain — an important comfort and safety factor, especially as the welding workforce ages.

Additional factors to consider

In addition to considering ClearLight Lens Technology, there are other factors to look for in choosing the right helmet.

A helmet that is properly balanced is just as critical as its weight, since both reduced weight and improved balance reduce neck strain and improve operator comfort. It can also help increase productivity by allowing for more arc-on time.

Headgear technology that uses flexible materials to provide a more secure fit and conform to each operator’s unique head shape and size can also improve comfort and efficiency. This type of helmet technology minimizes the irritation of pressure points that could lead to headaches.

ClearLight Lens Technology provides welders with a clearer view of their work — a key feature that helps prevent costly mistakes and rework by making it easier to see the weld pool. ClearLight Lens Technology can also reduce the potential for eye strain – making it more comfortable for operators to keep the helmet down.

When choosing a welding helmet, consider available lens technologies like ClearLight Lens Technology. Investing in a helmet capable of providing a brighter light state and a wider range of colors can help improve safety, compliance, productivity, and operator comfort in the welding operation.